Batch fermentation is a crucial process in various industries, playing a significant role in producing a wide range of products, including beer, antibiotics, enzymes, and biofuels. When exploring the process of Batch Fermentation, reputable scientific journals and research papers serve as a valuable source of knowledge. This article aims to delve into the intricacies of batch fermentation, exploring its fundamental aspects, applications, and advancements.

What is Batch Fermentation?

Batch fermentation is a biotechnological process where microorganisms are cultured in a closed system (bioreactor) with a fixed volume of nutrients and substrate. Unlike continuous fermentation, which maintains a constant flow of fresh nutrients, batch fermentation involves adding all the necessary components at the beginning of the process. The culture grows until the nutrients are depleted or waste products reach toxic levels, leading to the end of the fermentation cycle.

The Basics of Batch Fermentation Process

Definition

In batch fermentation, microorganisms are introduced to a bioreactor containing a predetermined amount of substrate and nutrients. They undergo growth, metabolizing the substrate and producing the desired product during various growth phases.

Advantages and Disadvantages

Batch fermentation offers several advantages, such as simplicity, ease of control, and versatility in handling different microorganisms. However, it also has some drawbacks, including longer production times, lower product yields, and the need for frequent manual interventions.

Key Components of Batch Fermentation

Substrate

The substrate serves as the primary source of energy for microorganisms during fermentation. It can be a carbon-rich compound, such as glucose or starch, depending on the microorganism and the desired end product.

Microorganisms

The selection of appropriate microorganisms is crucial in batch fermentation. Different strains possess varying abilities to metabolize the substrate and produce the desired product efficiently.

Bioreactor

The bioreactor, or fermentation vessel, provides a controlled environment for the microorganisms to grow and produce the target product. It includes systems for temperature regulation, pH control, oxygen supply, and agitation.

Nutrients and Environmental Factors

Microorganisms require various nutrients, such as nitrogen, phosphorus, and trace minerals, for growth and metabolism. Additionally, factors like temperature, pH level, and oxygen supply influence the fermentation process.

Stages of Batch Fermentation

Lag Phase

The lag phase is the initial stage of batch fermentation, characterized by slow or no growth of microorganisms. During this phase, cells adjust to the new environment, synthesize essential enzymes, and prepare for active growth.

Exponential (Log) Phase

The exponential phase is marked by rapid growth and cell division, resulting in a significant increase in cell biomass and product formation. This phase continues until the nutrients start depleting.

Stationary Phase

In the stationary phase, the growth rate of microorganisms slows down, and the production of the target product reaches a plateau. It occurs due to nutrient limitation or the accumulation of inhibitory by-products.

Death Phase

The death phase occurs when the growth conditions become unfavorable, and the number of viable microorganisms decreases. This phase is critical to determine the final product yield and purity.

Factors Influencing Batch Fermentation

Temperature

Temperature significantly affects the growth rate and metabolism of microorganisms. Maintaining an optimal temperature range is vital for achieving high product yields.

pH Level

The pH level influences the activity of enzymes and the stability of microorganisms. Proper pH control ensures optimal fermentation conditions.

Oxygen Supply

Adequate oxygen supply is essential for aerobic microorganisms to carry out efficient metabolism and growth. Insufficient oxygen can lead to reduced product yields and cell stress.

Agitation and Mixing

Proper agitation and mixing ensure uniform distribution of nutrients and prevent the formation of concentration gradients. This helps maintain a homogeneous environment for microorganisms.

Monitoring and Control in Batch Fermentation

Online Sensors

Online sensors play a crucial role in monitoring various parameters, such as temperature, pH, dissolved oxygen, and biomass concentration, in real-time. This data allows for timely adjustments and better process control.

Process Control Strategies

Automated control systems can regulate critical parameters, optimizing fermentation conditions for improved product yields and consistency.

Applications of Batch Fermentation

Brewing and Distilling

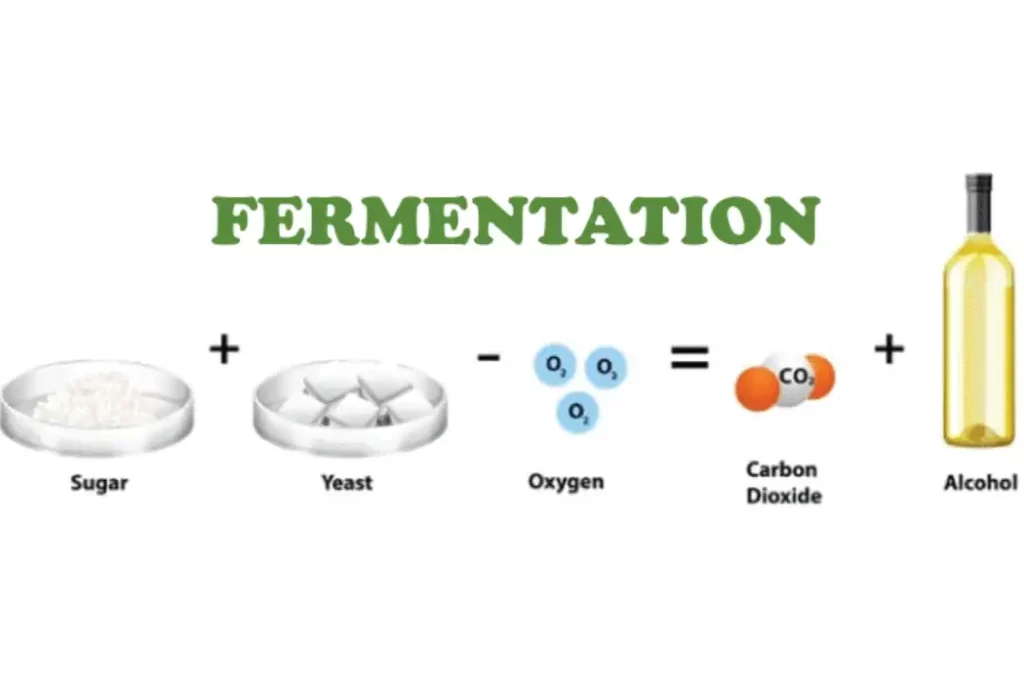

The brewing industry utilizes batch fermentation to produce beer, where yeast ferments the sugars in malted grains, creating alcohol and carbon dioxide.

Pharmaceutical Industry

Batch fermentation is used in pharmaceuticals to produce antibiotics, vaccines, and therapeutic proteins through microbial synthesis.

Food Industry

The food industry employs batch fermentation to produce various products, such as cheese, yogurt, and vinegar.

Environmental Biotechnology

In environmental biotechnology, batch fermentation helps in wastewater treatment and the production of biofuels from organic waste.

Advancements in Batch Fermentation Techniques

Fed-batch Fermentation

Fed-batch fermentation involves the continuous addition of nutrients during the fermentation process. This approach improves product yields and reduces by-product formation.

Continuous Batch Fermentation

Continuous batch fermentation allows the removal of a fraction of the culture at regular intervals while maintaining a constant volume. This process facilitates prolonged fermentation and higher productivity.

Metabolic Engineering

Metabolic engineering techniques enable the modification of microorganisms’ metabolic pathways, enhancing their ability to produce specific products efficiently.

Conclusion

Batch fermentation is a versatile and widely-used biotechnological process with applications across various industries. By understanding its key components, stages, and influencing factors, scientists and engineers can enhance product yields, improve efficiency, and contribute to sustainable manufacturing practices.

FAQs

Q: What is batch fermentation?

Answer: Batch fermentation is a biotechnological process where microorganisms are cultured in a closed system with fixed nutrients and substrate until the fermentation cycle is complete.

Q: What are the applications of batch fermentation?

Answer: Batch fermentation is used in industries such as brewing, pharmaceuticals, food production, and environmental biotechnology.

Q: What challenges does batch fermentation face?

Answer: Challenges include process optimization, cost reduction, and maintaining product purity.